Additive manufacturing explores the 4th dimension to make objects evolve

In its latest issue (March 2022), Industrie & Technologies magazine highlighted additive manufacturing and 4D printing. A first part, centered on the 3D printing process invented by Jean-Claude André from the University of Lorraine (DR CNRS emeritus of the INSIS Institute of the CNRS) followed by his research activities with Frédéric Demoly, Professor of Universities (UTBM/ICB) and his team.

Will 4D printing be the next big thing in additive manufacturing?

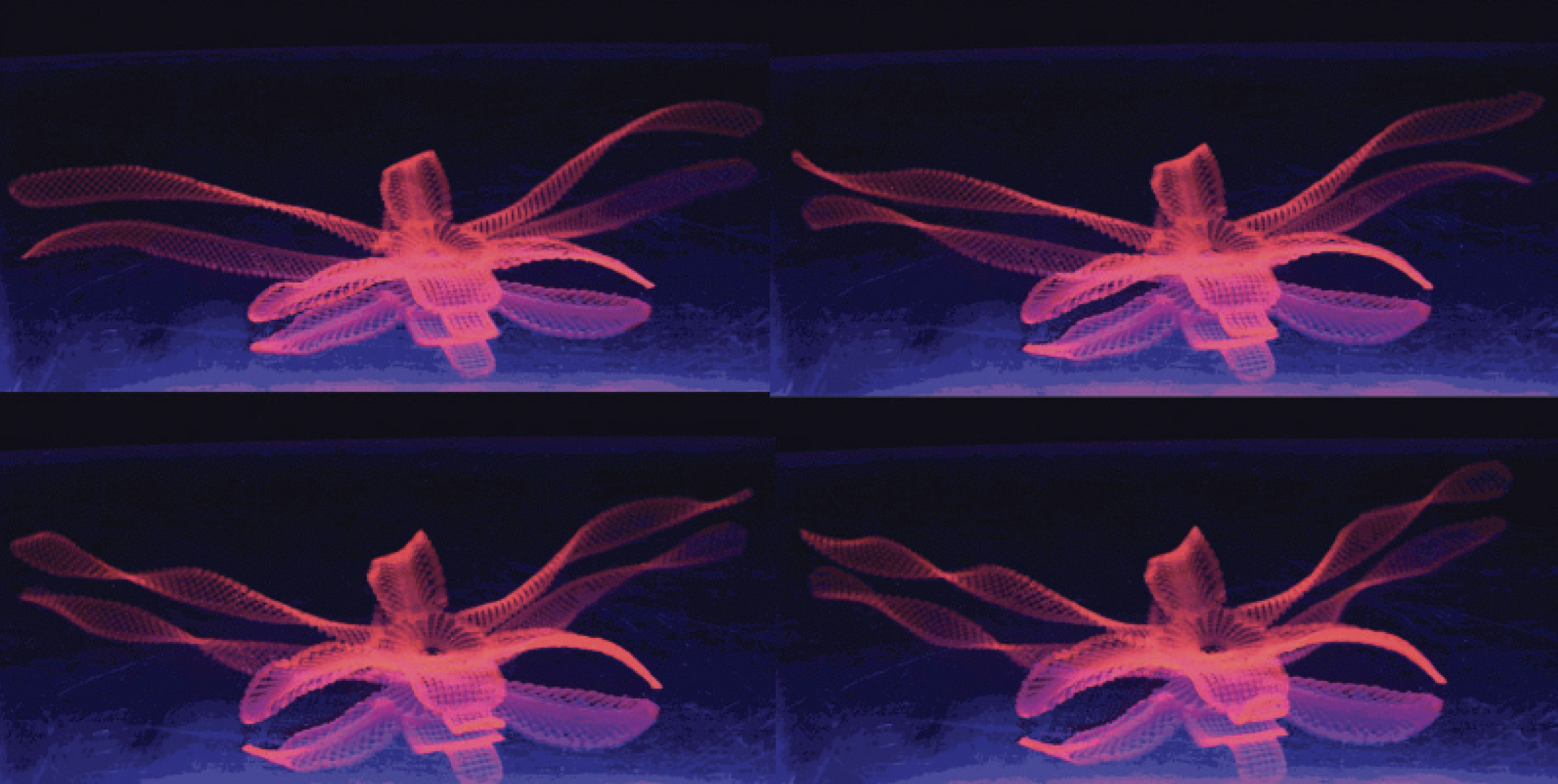

In any case, this is the opinion of its promoters, including Frédéric Demoly, professor at the University of Technology of Belfort-Montbéliard (UTBM). This fourth dimension designates an external condition – temperature, pH, magnetic field or passage of time – which comes to solicit a reactive material contained in the object. It can thus change shape or properties depending on its environment.

It will have taken almost thirty years of development to see additive manufacturing impose itself in our daily lives and diversify, now making it possible to produce in polymer, metal or ceramic 3-dimensional (3D) objects of shapes inaccessible by conventional means. 4D printing is a technology that combines additive manufacturing and active materials under the effect of stimulation (electric and/or magnetic fields, light, temperature, pH, etc.). It allows 3D objects to have the ability to change properties, shapes and functionalities over time. However, the currently controlled 4D printing leads to objects with low performance in response time and mechanical strength.

- Contact : frederic.demoly@utbm.fr

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content:

- [kc_row use_container="yes" force="no" column_align="middle" video_mute="no" _id="448091"][kc_column width="12/12" video_mute="no" _id="711823"][kc_column_text _id="791117"]

In its latest issue (March 2022), Industrie & Technologies magazine highlighted additive manufacturing and 4D printing. A first part, centered on the 3D printing process invented by Jean-Claude André from the University of Lorraine (DR CNRS emeritus of the INSIS Institute of the CNRS) followed by his research activities with Frédéric Demoly, Professor of Universities (UTBM/ICB) and his team.

[/kc_column_text][kc_spacing height="41px" _id="671405"][/kc_column][/kc_row][kc_row use_container="yes" _id="201386"][kc_column width="45%" _id="88455"][kc_column_text _id="764055"]Closer look at

[/kc_column_text][kc_spacing height="20px" _id="479477"][kc_single_image image_size="full" _id="803689" image_source="media_library" image="24502" on_click_action="op_large_image"][/kc_column][kc_column width="5%" _id="136960"][/kc_column][kc_column width="50%" _id="1201"][kc_column_text _id="36545"]Will 4D printing be the next big thing in additive manufacturing?

[/kc_column_text][kc_spacing height="20" _id="278927"][kc_column_text _id="560425"]

[/kc_column_text][kc_spacing height="5px" _id="928058"][kc_column_text _id="396247"]In any case, this is the opinion of its promoters, including Frédéric Demoly, professor at the University of Technology of Belfort-Montbéliard (UTBM). This fourth dimension designates an external condition - temperature, pH, magnetic field or passage of time - which comes to solicit a reactive material contained in the object. It can thus change shape or properties depending on its environment.

It will have taken almost thirty years of development to see additive manufacturing impose itself in our daily lives and diversify, now making it possible to produce in polymer, metal or ceramic 3-dimensional (3D) objects of shapes inaccessible by conventional means. 4D printing is a technology that combines additive manufacturing and active materials under the effect of stimulation (electric and/or magnetic fields, light, temperature, pH, etc.). It allows 3D objects to have the ability to change properties, shapes and functionalities over time. However, the currently controlled 4D printing leads to objects with low performance in response time and mechanical strength.

[/kc_column_text][kc_spacing height="20" _id="881941"][kc_column_text _id="308334"] [/kc_column_text][kc_spacing height="10px" _id="907001"][kc_column_text _id="422727"]- Contact : frederic.demoly@utbm.fr