The project will bring together Prof. Bernard's team within the Carnot Interdisciplinary Laboratory in Burgundy (ICB, UMR 6303 CNRS-UBFC), the Innovation Laboratory for New Energy Technologies and Nanomaterials at CEA in Grenoble, the Center de Shaping of materials (UMR 7635 CNRS-Paris Sciences Lettres / Mines ParisTech) and the company Framatome. This partnership provides the CALHIPSO project with a rich scientific environment and complementary equipment both from the point of view of manufacturing processes and that of means of characterization.

Center of Excellence in Powder Metallurgy (EXCALIBURE)

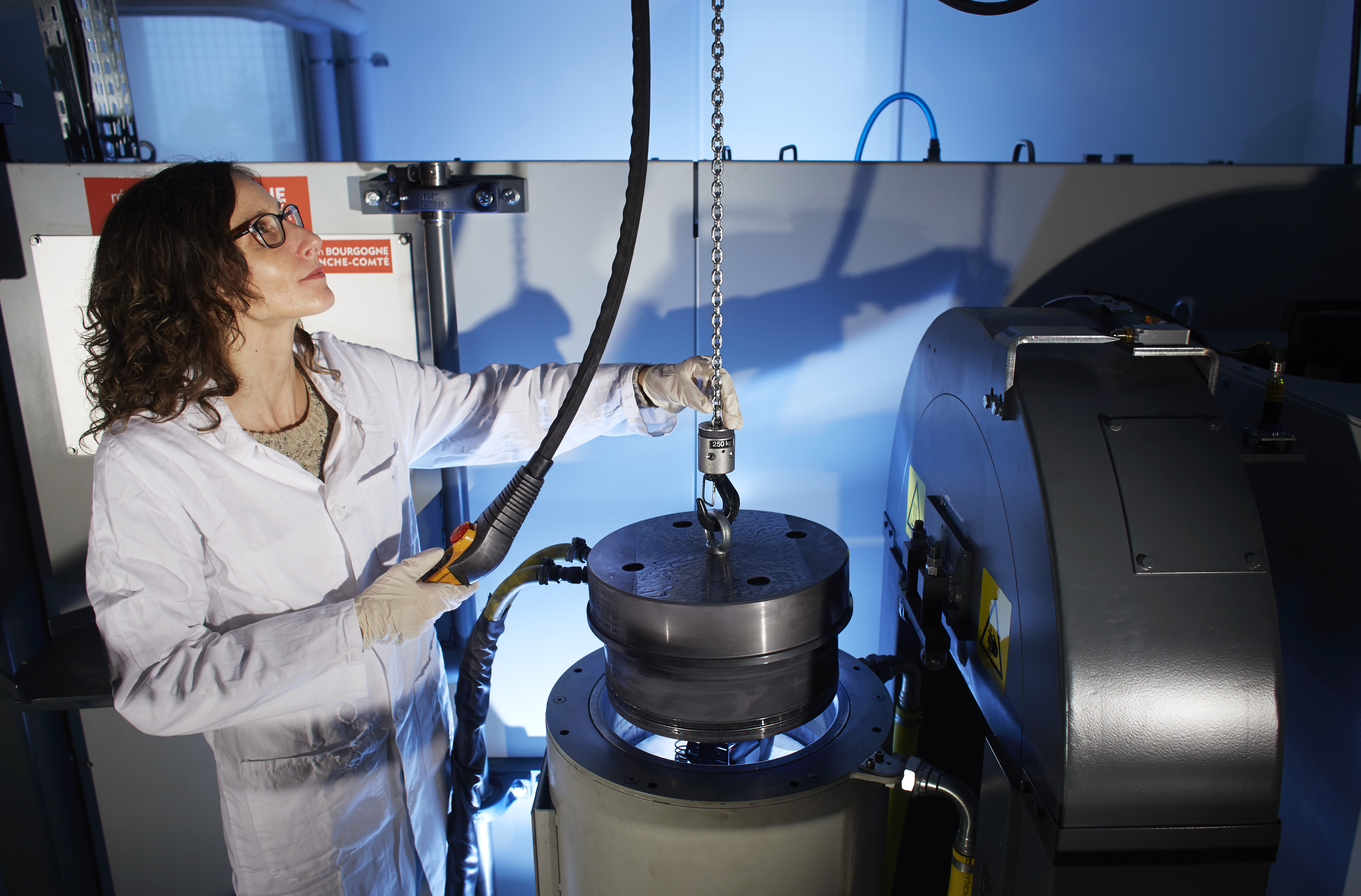

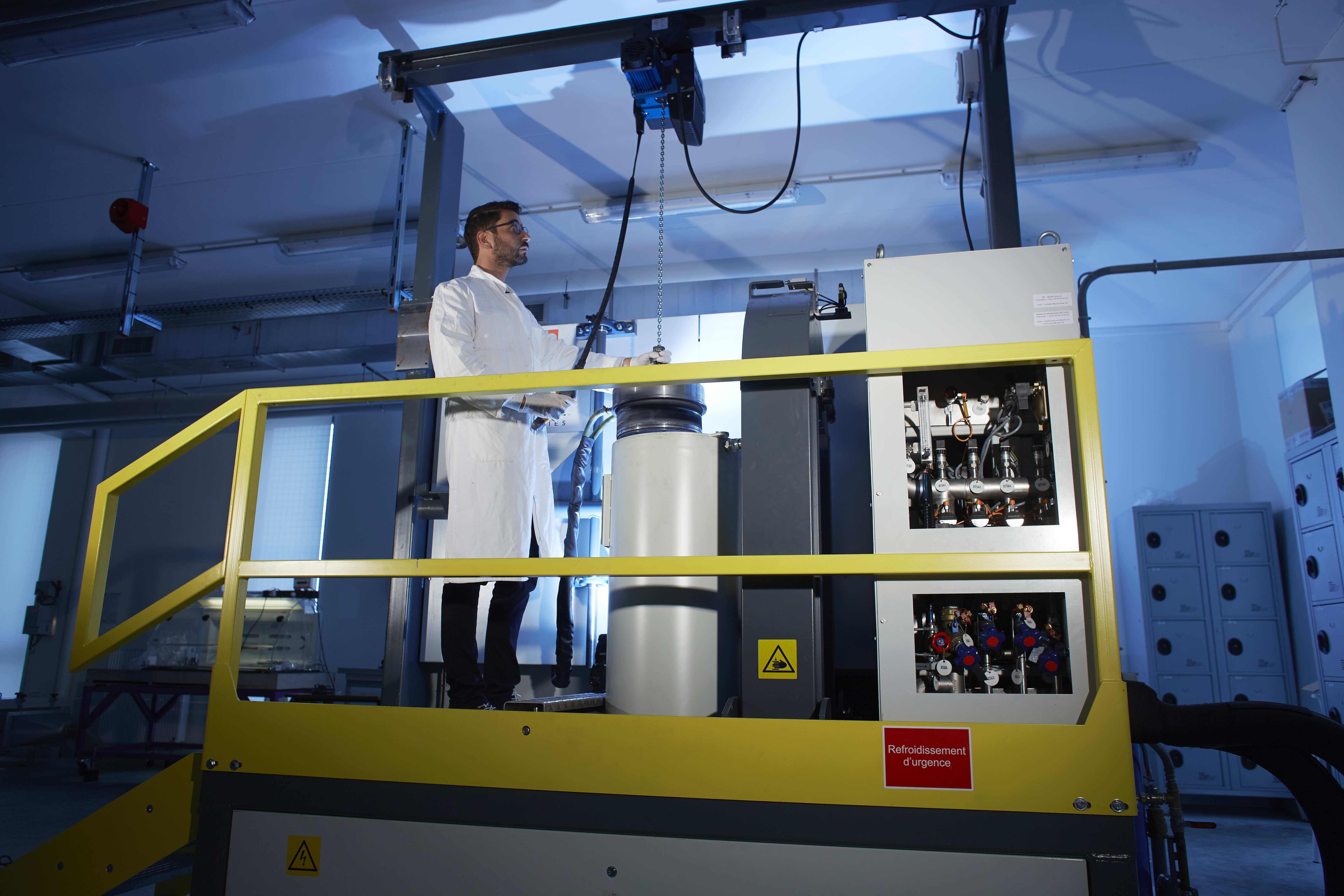

A team of experts, over 20 years in powder metallurgy manufacturing, develops innovative solutions for your products tailored to your needs. By using EXCALIBURE you access a cutting-edge technological environment to develop your activity.

Frédéric BERNARD

Manager

fbernard[at]u-bourgogne.fr

Phone : +33 (0)3 80 39 61 25

Make your parts by powder metallurgy !

We support you from the design phase to the realization of the final part, by the use of powder metallurgy techniques for the manufacture of metal or ceramic parts and / or assemblies.

Powder metallurgy allows the manufacture of parts or assemblies of complex shape. Thanks to this, make your products using these techniques using innovative materials.

Technological excellence at your service

A team of experts, over 20 years in powder metallurgy manufacturing, develops innovative solutions for your products tailored to your needs. By using EXCALIBURE, you access a cutting-edge technological environment to develop your activity. EXCALIBURE respects the confidentiality of your projects and information.

Our know-how at your disposal

We offer personalized support and we use all our skills which bring together experts (teachers, R&D engineers, technicians, etc.) as well as our equipment to meet your request.

Several advantages

- Making complex shaped parts

- Develop “innovative (composition and / or microstructure)" alloy parts in order to improve their performance in service

- Implement heat treatments of parts from conventional manufacturing and improve properties (closure of porosity within materials and parts).

- Limit machining operations and reduce consumption of raw materials (60% to 80%)

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content: