Thermal and/or electrochemical corrosion of metals and alloys

Durability of metallic materials in complex atmospheres at high temperature

- Study of high temperature degradation of metals and alloys in aggressive atmospheres at high temperature (chromia- and alumina-forming alloys, intermetallics, low Cr steels). Long term experiments

- Coupling characterization tools to understand corrosion mechanism at high temperature (in-situ XRD, TEM, XPS, SIMS, SEM), use of isotopic markers in two-stage oxidation experiments in order to elucidate oxide scale growth mechanism at high temperature

- Use of in-situ synchrotron diffraction

- Mechanism of corrosion of titanium alloys at high temperature in presence of solid salt deposits (NaCl, Na2SO4, NaCl-Na2SO4)

- Ageing and degradation of metallic alloys elaborated by additive manufacturing

- Materials for energy and sustainable development: development of materials, coatings or technical solutions for turbines, nuclear power plants, solid-oxide fuel cells (SOFC), solid-oxide electrolysers (SOE), hydrogen.

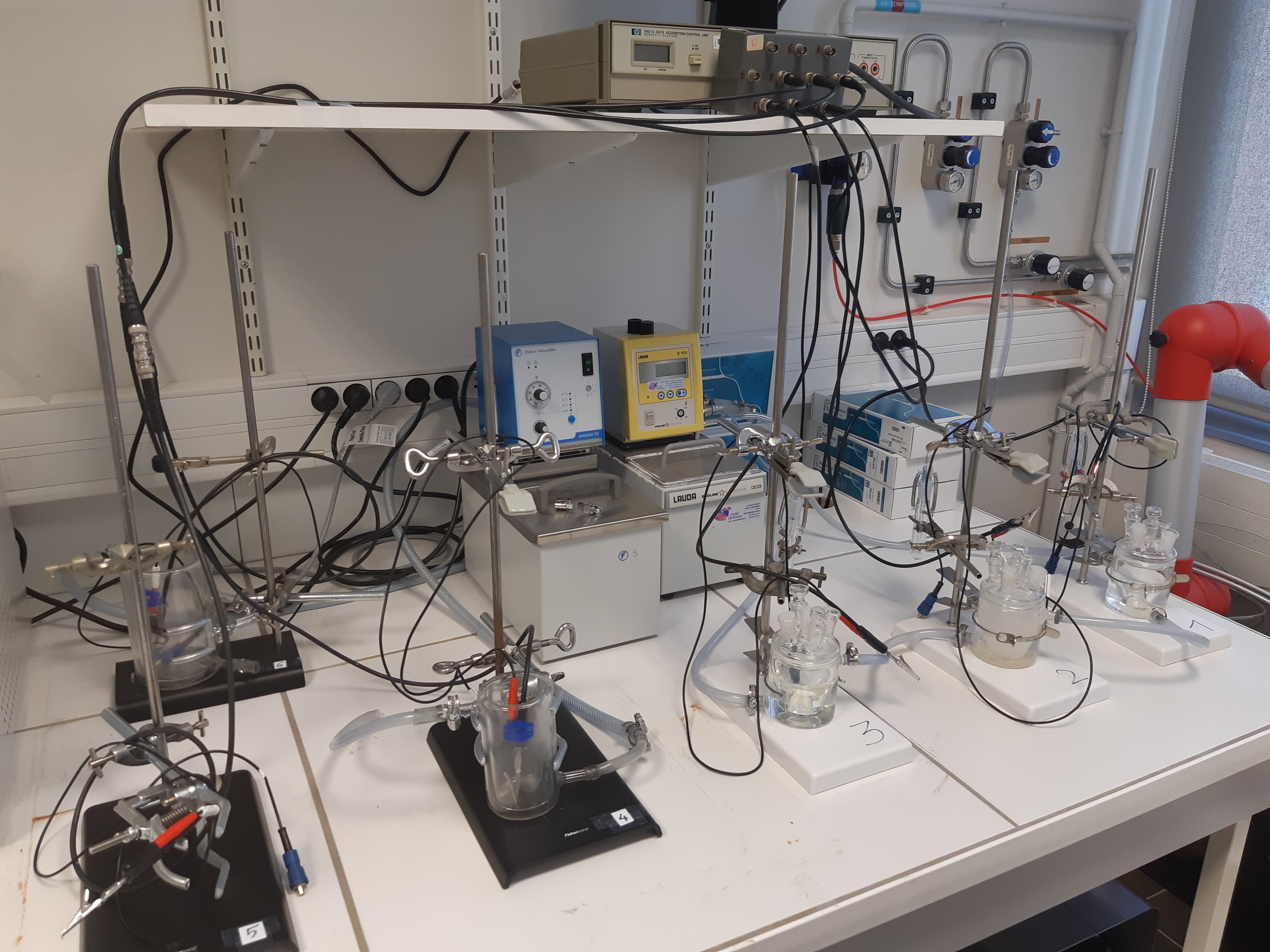

Tools for high temperature durability: TGA, cyclic tests, muffle furnaces, water vapor device, surface treatment, in-situ electrical measurements….

Keywords: high temperature corrosion, complex atmospheres, water vapor, solid salt deposits, long term studies, steels, titanium alloys

Contact : Vincent Vignal

Corrosion of metallic alloys in aqueous solutions

Understanding the reactivity of solution/passive film/substrate interfaces and indentifying the basic processes leading to the passive film breakown and metal dissolution

- Degradation of materials, including passivation and localized corrosion of metals, alloys and assemblies

- Relationships between microstructure – mechanical stress/strain – corrosion

- Influence of industrial processes: machining, welding, surface preparation methods…

- Influence of long-term ageing under representative conditions (in humide gaz, liquids, salt fogs…)

- Multi-scale and multi-disciplinary approaches : global and local techniques in electrochemitry, mechanics and surface characterization

Applied Research: LIMPE – LRC n° DAM-VA-11-02 (created in 2011), projects with industrial partners, several patents deposited

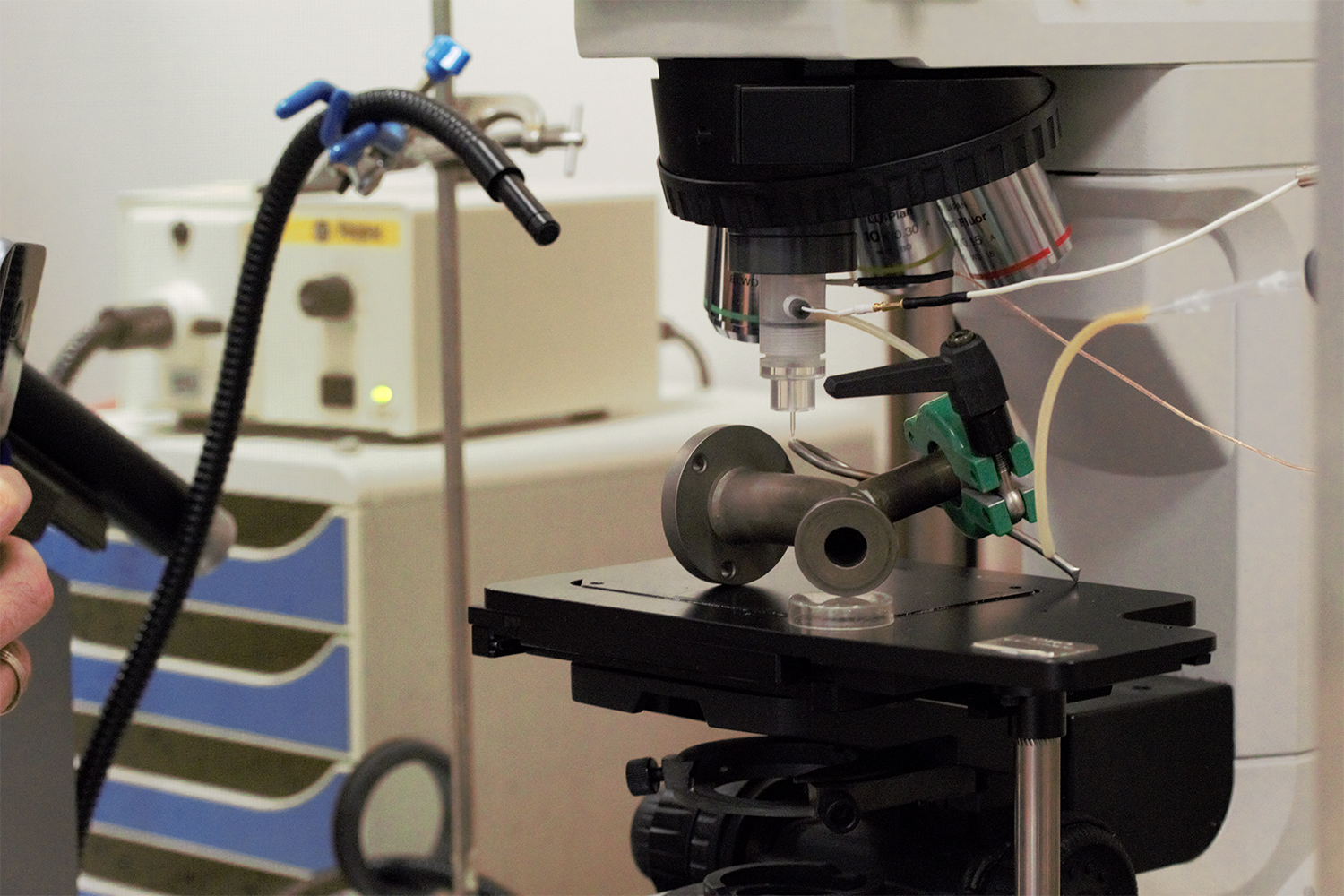

Main tools for corrosion investigations: Electrochemical microcell techniques, Autoclave, ageing cells, CPT, Electrodeposition, AFM,…

Keywords: Corrosion in aqueous solutions, passive films, microstructure, stress/strain, industrial processes, long-term ageing, electrodeposition,…

Stress-diffusion-reaction interactions in solid/solid reactive systems. Experimental and numerical approaches

Theoretical and experimental studies of the interactions between mechanics, diffusion and reactivity in metallic solids.

- Improving the corrosion resistance of alloys at high temperature, by using mechanical surface treatments (laser shock peening, shot peening, water blasting, friction stir)

- The main material used for our applications is titanium alloys to improving the durability of aeronautics compounds, under temperature conditions above 500°C.

- The processes explored are oxidation and hydriding

- Simulation tools at the macroscopic scale are finite element codes that incorporate specific behavior laws: CASTEM, ABAQUS, FORGE

Mean experimental tool: an autoclave which makes it possible to reach a pressure of 290 bars and/or a temperature of 650 ° C.

Keywords: stress-diffusion coupling, oxidation, high temperature, hydriding, mechanical surface treatments.

Contact : Tony Montesin

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content: