The PMDM department has know-how in the field of powder metallurgy both in terms of design by different technologies (atomization, agglomeration, synthesis), in terms of materials (metals, ceramics, polymers, composites etc.), and both in terms of the production of massive parts by the compaction and additive manufacturing processes.

Development of powders

Metal powders by atomization

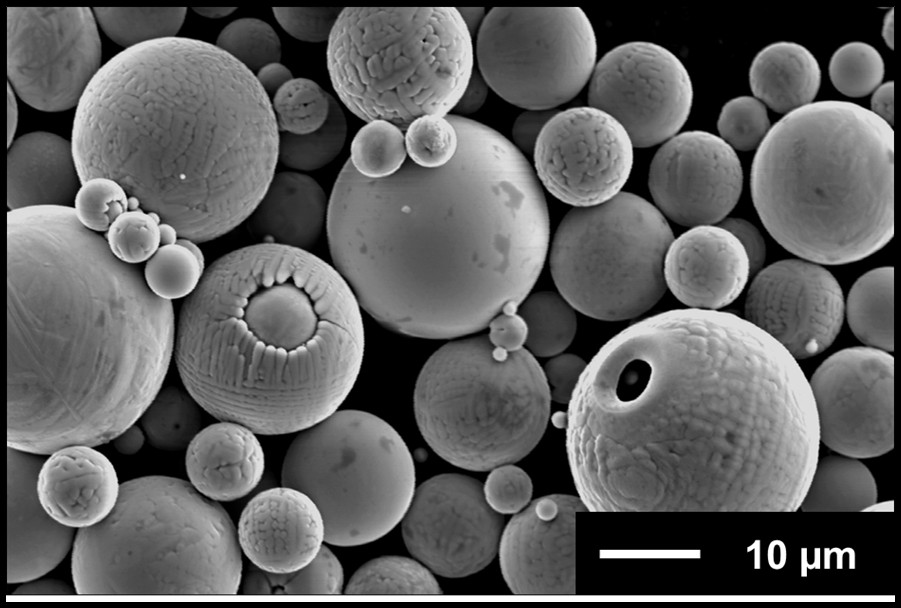

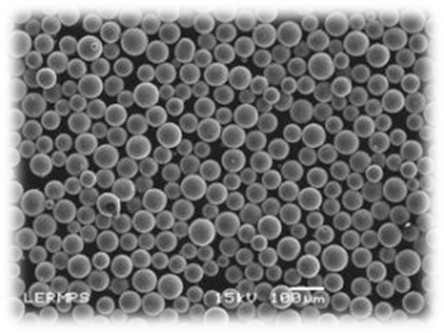

The principle of atomization is the spraying into fine droplets of a stream of molten material using a jet of gas under high pressure. The droplets solidify and give the powder. Through the use of an atomizing nozzle with a “Laval" profile, the gas flow is laminar. Thus the size of the droplets is better controlled and therefore the particle size distribution of the powder produced as well. It is therefore tightened and can be moved to a finer particle size.

{slide = atomized materials}

- Ni base (Waspaloy, Inconel625, 718, 100 …)

- Fe base (Inox316L, 304L, Maraging steel, FeAl, K41X, Cast iron …)

- Co base (CoCrMo, Stellites …)

- Al base (AS7G06, AlSi10Mg, A2017 …)

- Cu base

{/ slide}

{slide = Characterization of lots}

- analysis of the particle size distribution according to ISO13320

- composition analysis by EDS with SEM or by ICP-AES (subcontracting)

- light element analysis: O, N, H, S, C

- flowability analysis

- bulk density analysis according to ISO3953

{/ slide}

{slide = Post-processing}

- sifters and classification (elutriation) in air or in an inert atmosphere (nitrogen or argon)

{/ slide}

Contact :

Yoann Danlos – Phone : +33 (0)3 84 58 32 76 – yoann.danlos[at]utbm.fr

Ceramic powders, composite by agglomeration

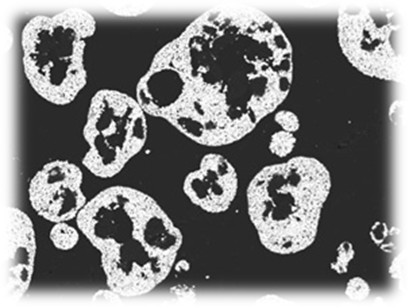

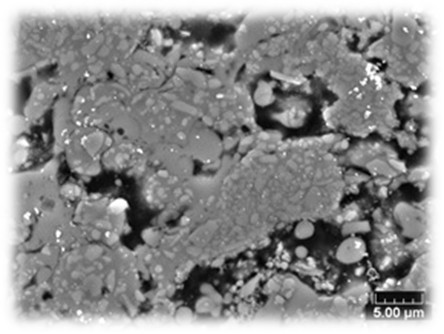

Spray drying is a process for shaping powders from a suspension of micron or sub-micron particles. The average sizes of agglomerates produced with laboratory tools vary from 10 to 120 µm. This process leads to the formation of spherical granules making it possible to improve the flowability and / or to ensure chemical homogeneity of the powders produced. In fact, this process can be judiciously used to develop new ceramic powder compositions, to develop ceramic / polymer composite powders or metal / carbide cermets. In addition to the composition, the drying agglomeration process makes it possible to control the morphology of the granule formed through rigorous control of the different stages:

- slip formulation (stability, homogeneity, behavior)

- spraying and drying (drop size and distribution, drying speed and drying mode)

- consolidation (oven, flame or plasma torch treatment)

Contact :

Pierre Bertrand – Phone: +33 (0)3 84 58 32 46 – pierre.bertrand[at]utbm.fr

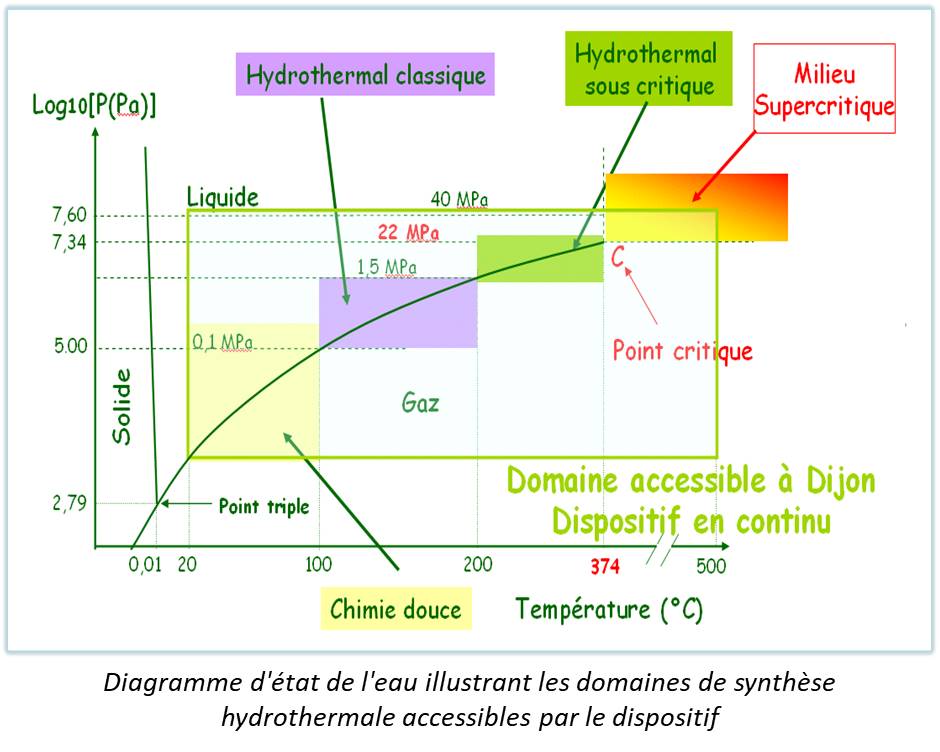

Synthesis of nanopowders in solvothermal medium

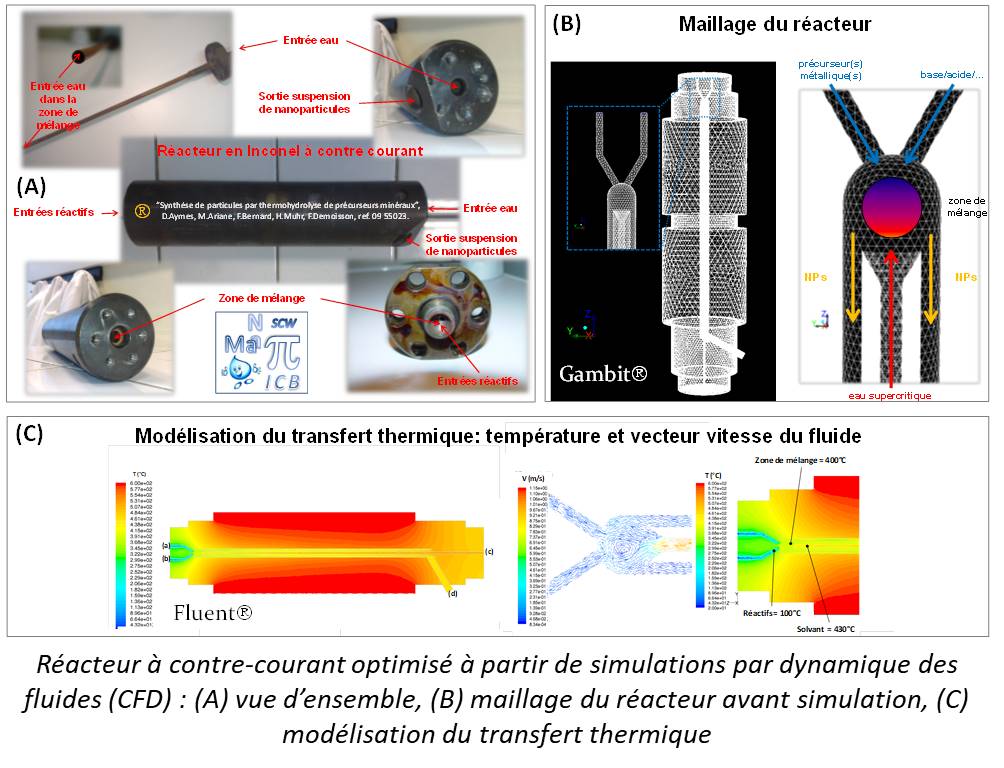

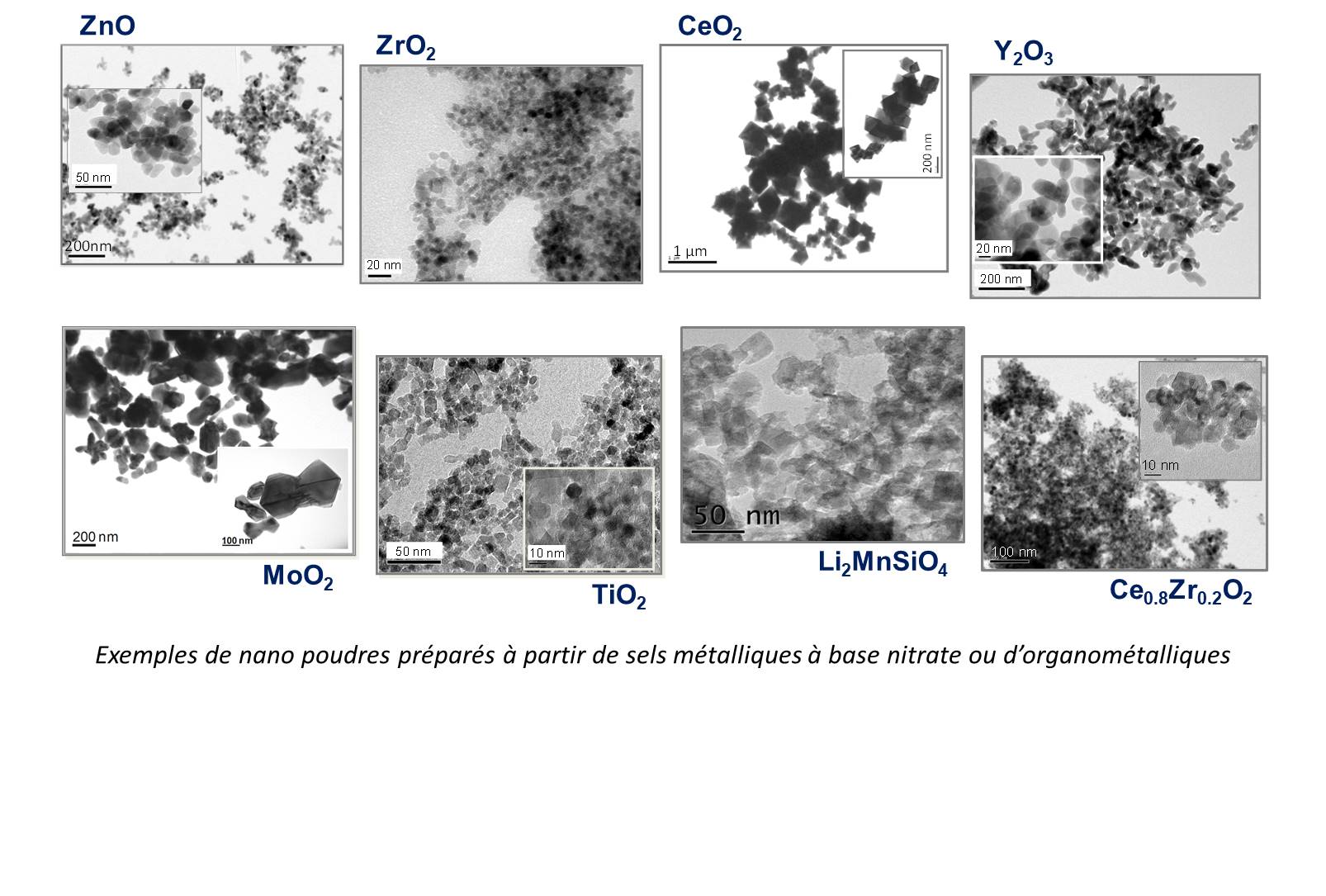

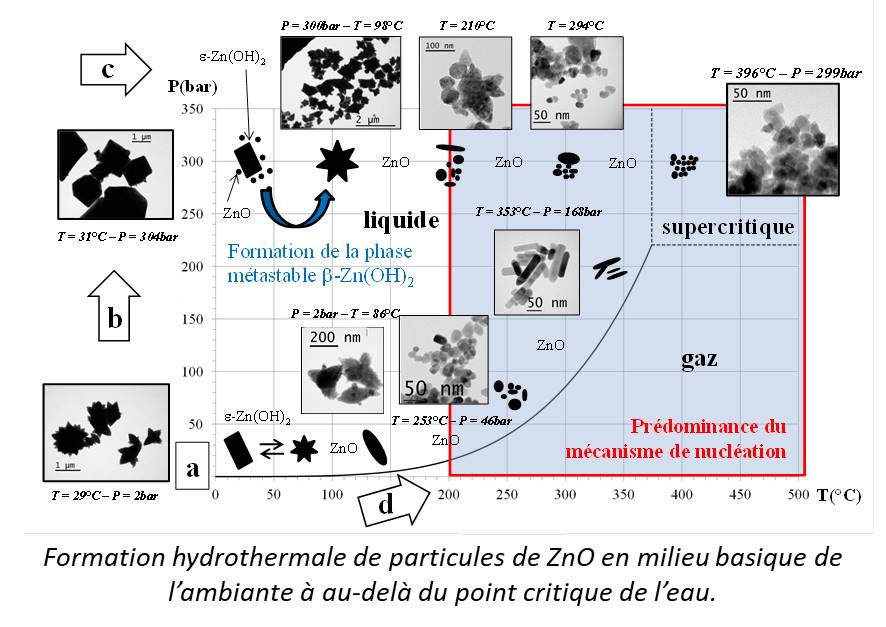

The prospects for industrial use of nanomaterials are growing every day, especially those of nanostructured oxides. The production routes for these nanopowders are varied, but it will be imperative in the short term to have materials of excellent quality, for example without crystal defects or whose surface will not contain essential adsorbed species other than H2O or OH-. In addition, it is now important to develop clean and environmentally friendly synthetic routes. Among all the possible synthetic routes, the synthesis of nanopowders in a solvothermal medium has many advantages and responds in particular to the constraints described above. In fact, the thermohydrolysis process that occurs generally does not require secondary reagents, hence a “clean" reaction medium: which considerably limits pollutant releases.

Synthesis in supercritical water has been around for a long time in batch reactors. The main drawback of such a closed device is the thermal inertia of the reactor which must “resist" the combined effect of temperature and pressure, and the resulting temperature variations in the reaction medium. These limitations can be removed in a continuous device. The continuous supercritical water synthesis implemented by the PMDM axis has shown its ability to produce many simple and mixed oxides (Fe2O3, Fe3O4, CoFe2O4, TiFe2O4, TiO2, ZrO2, BaZrO3, …). The current laboratory system allows an average production of 10 to 15 g / h of dry powder. Particles of nanometric sizes are generally very well crystallized and do not require any additional heat treatment, after recovery; this is a considerable advantage of this type of synthesis compared to syntheses by soft chemistry.

Contact :

Frédéric Demoisson – Phone: +33 (0)3 80 39 59 06 – frederic.demoisson[at]u-bourgogne.fr

Massive parts

The PMDM department has a specialization in the development and characterization of sintered materials by hot compaction, as well as the assembly of dissimilar materials without addition of material, involving metallic materials (pure metals and alloys) and ceramics (oxides and carbides ). To establish the process / microstructure / properties relationships, our objective is to understand the elementary mechanisms that develop at different scales such as the germination and growth mechanisms, the densification mechanisms, phase transformations and structural transformations.

Compaction

We develop several tools and processes:

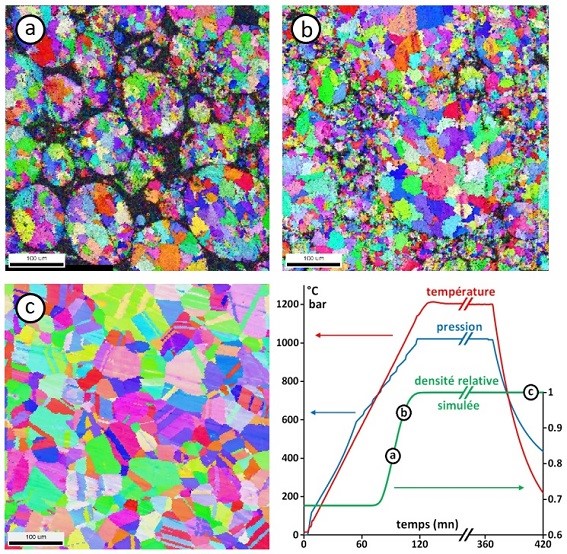

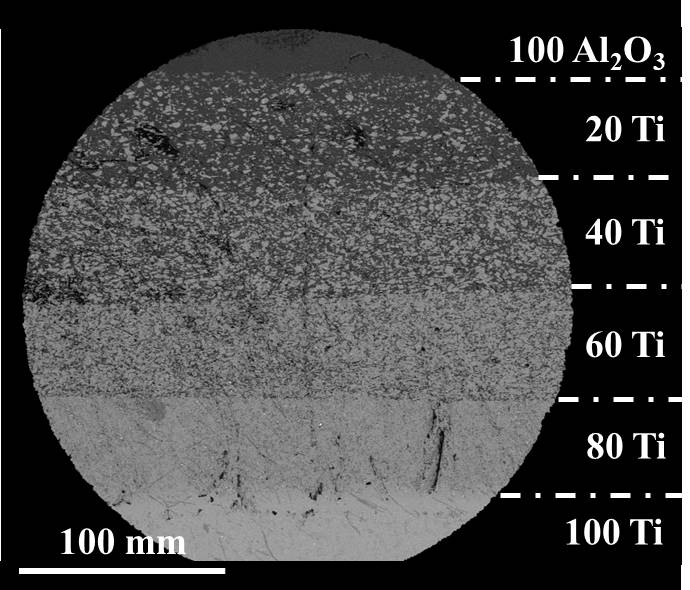

- flash sintering or SPS (Spark Plasma Sintering) under uni-axial load and heating by conduction / Joule effect: screening of materials / microstructures, dense materials with controlled microstructure, materials with a functional gradient, implementation of parts by self-assembly

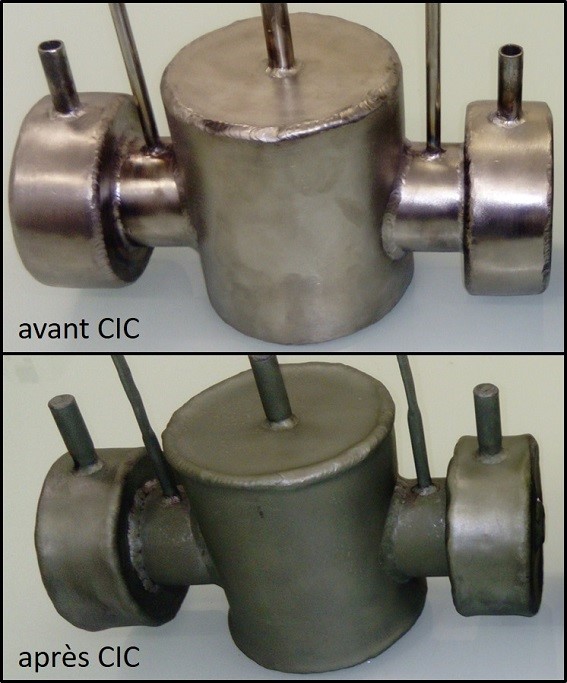

- isostatic hot compaction (CIC) with isostatic stress and convection heating. It makes it possible to envisage different aspects: implementation of parts of complex shapes, dense materials with homogeneous microstructures, closure of the porosity (foundry defects, parts obtained by additive manufacturing, etc.), assembly by diffusion in the solid state.

Contacts :

Frédéric Bernard – Phone: +33 (0)3 80 39 61 25 – fbernard[at]u-bourgogne.fr

Sophie Le Gallet – Phone: +33 (0)3 80 39 61 63 – Sophie.Le-Gallet[at]u-bourgogne.fr

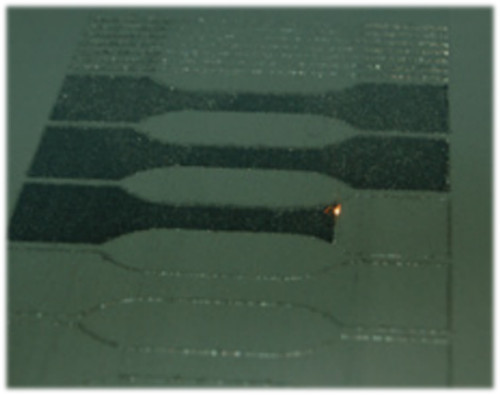

Additive manufacturing

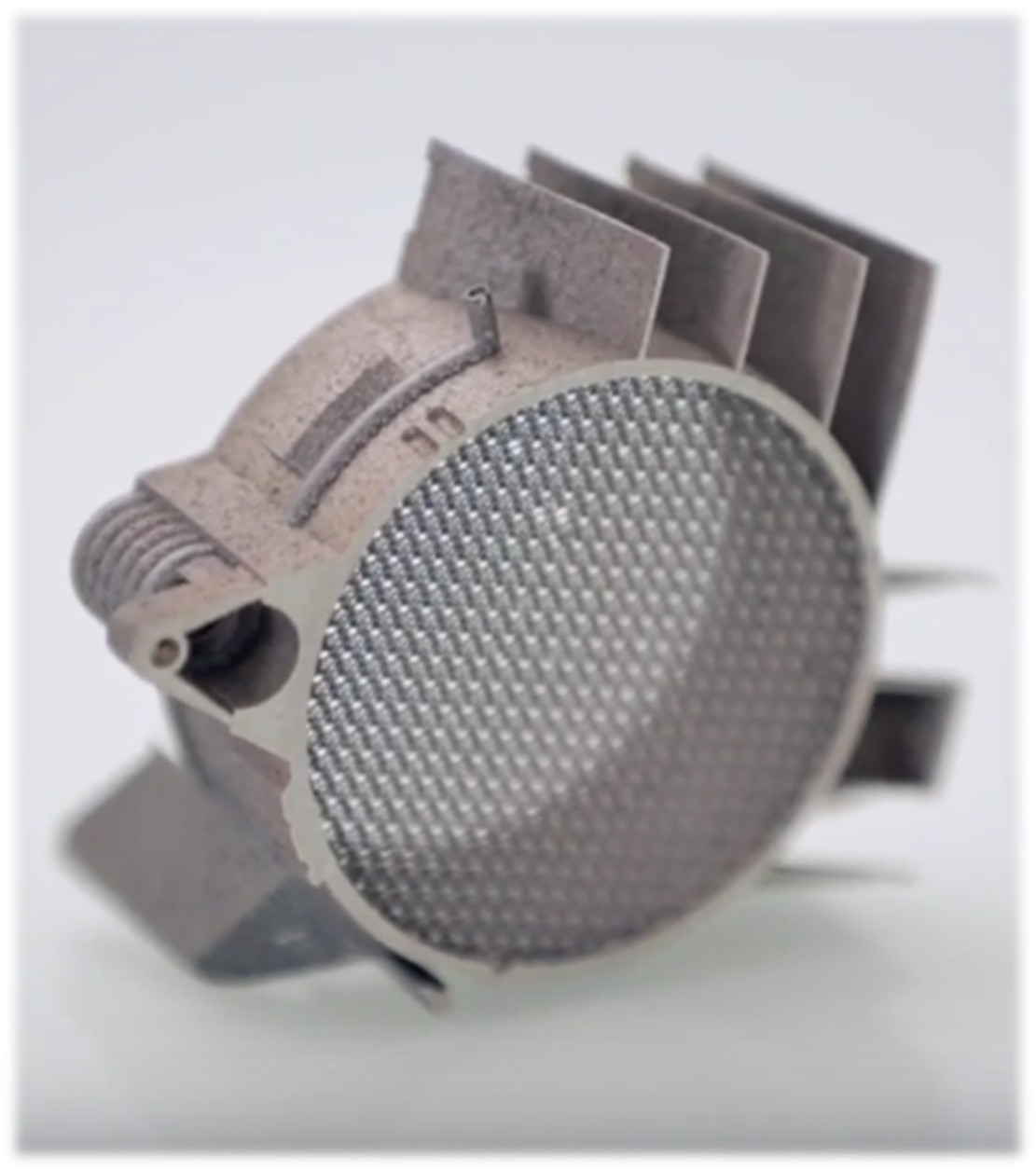

The additive manufacturing process by laser micro-fusion on a powder bed (SLM: Sintering Laser Melting) consists of placing a bed of powder a few tens of micrometers thick on a support plate, then melting this powder according to the parameters. geometric defined from a CAD file. The molten powder is solidified quickly forming beads of solid material. At the end of this step, the support plate comes down to a layer thickness and a movable container deposits powder. Then the process starts again to develop another layer of material. This is repeated until the finished product.

Contacts :

Christophe Verdy – Phone:+33 (0)3 84 58 31 08 – Christophe.verdy@utbm.fr

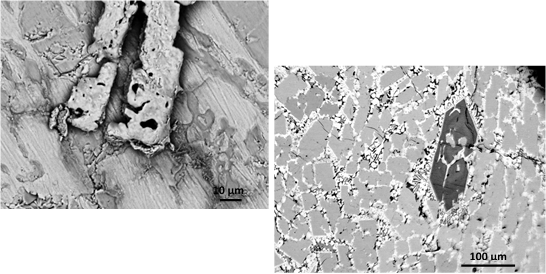

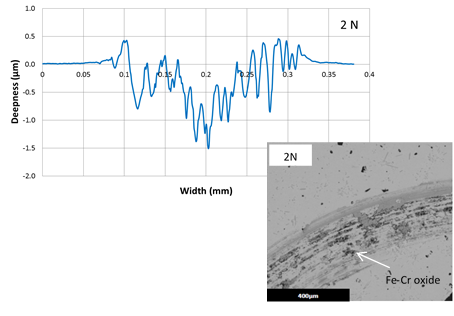

Durability of sintered materials

Optimizing the wear properties of metals and metal alloys developed by SPS and HIP, leading to an extension of the service life of parts in service condition, constitutes an important technical challenge. The processing parameters directly influence the microstructure and, therefore, the durability properties of the products obtained by powder metallurgy. The study of the durability of sintered materials is approached from several aspects:

- evaluation of mechanical (initial condition and in service conditions) and tribological properties;

- resistance to high temperature oxidation;

- weldability;

- modeling of structural changes in relation to the final properties.

Contacts :

Maria-Rosa Ardigo-Besnard – Phone: +33 (0)3 80 39 60 16 – maria-rosa.ardigo-besnard[at]u-bourgogne.fr

Jean-Philippe Chateau-Cornu – Phone: +33 (0)3 80 39 61 46 – jean-philippe.chateau-cornu@u-bourgogne.fr

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content:

- [kc_row use_container="yes" _id="301887"][kc_column width="100%" video_mute="no" _id="600862"][kc_column_text _id="356086"]

The PMDM department has know-how in the field of powder metallurgy both in terms of design by different technologies (atomization, agglomeration, synthesis), in terms of materials (metals, ceramics, polymers, composites etc.), and both in terms of the production of massive parts by the compaction and additive manufacturing processes.

[/kc_column_text][/kc_column][/kc_row][kc_row use_container="yes" _id="785581"][kc_column width="12/12" video_mute="no" _id="741928"][kc_spacing height="30px" _id="379550"][/kc_column][/kc_row][kc_row use_container="yes" _id="394376" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInDown||"][kc_column width="12/12" video_mute="no" _id="667609"][kc_column_text _id="999667"]Development of powders

[/kc_column_text][/kc_column][/kc_row][kc_row use_container="yes" _id="616829"][kc_column width="12/12" video_mute="no" _id="108616"][kc_spacing height="30px" _id="865006"][/kc_column][/kc_row][kc_row use_container="yes" _id="585977" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInLeft||"][kc_column width="55%" video_mute="no" _id="266775"][kc_column_text _id="591436"]Metal powders by atomization

The principle of atomization is the spraying into fine droplets of a stream of molten material using a jet of gas under high pressure. The droplets solidify and give the powder. Through the use of an atomizing nozzle with a "Laval" profile, the gas flow is laminar. Thus the size of the droplets is better controlled and therefore the particle size distribution of the powder produced as well. It is therefore tightened and can be moved to a finer particle size.

[/kc_column_text][kc_spacing height="20" _id="648861"][kc_column_text _id="902253"]{slide = atomized materials}

- Ni base (Waspaloy, Inconel625, 718, 100 ...)

- Fe base (Inox316L, 304L, Maraging steel, FeAl, K41X, Cast iron ...)

- Co base (CoCrMo, Stellites ...)

- Al base (AS7G06, AlSi10Mg, A2017 ...)

- Cu base

{/ slide}

{slide = Characterization of lots}

- analysis of the particle size distribution according to ISO13320

- composition analysis by EDS with SEM or by ICP-AES (subcontracting)

- light element analysis: O, N, H, S, C

- flowability analysis

- bulk density analysis according to ISO3953

{/ slide}

{slide = Post-processing}

- sifters and classification (elutriation) in air or in an inert atmosphere (nitrogen or argon)

{/ slide}

[/kc_column_text][kc_spacing height="20" _id="332365"][kc_column_text _id="726004"]Contact :

Yoann Danlos – Phone : +33 (0)3 84 58 32 76 – yoann.danlos[at]utbm.fr

[/kc_column_text][/kc_column][kc_column width="5%" video_mute="no" _id="285818"][/kc_column][kc_column width="40%" video_mute="no" _id="167174"][kc_carousel_images img_size="full" items_number="1" tablet="2" mobile="1" speed="500" pagination="__empty__" auto_play="__empty__" alt_text="yes" _id="290785" onclick="lightbox" images="12968,12972,12973,12970,12971,12969" navigation="yes" nav_style="arrow" auto_height="yes"][/kc_column][/kc_row][kc_row use_container="yes" _id="31208"][kc_column width="12/12" video_mute="no" _id="286481"][kc_spacing height="30px" _id="950535"][/kc_column][/kc_row][kc_row use_container="yes" _id="739420" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInRight||" container_class="full bg-rs"][kc_column width="2%" video_mute="no" _id="753430"][/kc_column][kc_column width="35%" video_mute="no" _id="213081"][kc_spacing height="20" _id="89902"][kc_carousel_images img_size="full" items_number="1" tablet="2" mobile="1" speed="500" pagination="__empty__" auto_play="__empty__" alt_text="yes" _id="984444" images="12977,12975,12974,12976" onclick="lightbox" navigation="yes" nav_style="arrow" auto_height="yes"][kc_spacing height="20" _id="414708"][/kc_column][kc_column width="6%" video_mute="no" _id="593201"][/kc_column][kc_column width="55%" video_mute="no" _id="41571"][kc_spacing height="20" _id="558504"][kc_column_text _id="536979"]Ceramic powders, composite by agglomeration

Spray drying is a process for shaping powders from a suspension of micron or sub-micron particles. The average sizes of agglomerates produced with laboratory tools vary from 10 to 120 µm. This process leads to the formation of spherical granules making it possible to improve the flowability and / or to ensure chemical homogeneity of the powders produced. In fact, this process can be judiciously used to develop new ceramic powder compositions, to develop ceramic / polymer composite powders or metal / carbide cermets. In addition to the composition, the drying agglomeration process makes it possible to control the morphology of the granule formed through rigorous control of the different stages:

- slip formulation (stability, homogeneity, behavior)

- spraying and drying (drop size and distribution, drying speed and drying mode)

- consolidation (oven, flame or plasma torch treatment)

Contact :

Pierre Bertrand – Phone: +33 (0)3 84 58 32 46 – pierre.bertrand[at]utbm.fr

[/kc_column_text][kc_spacing height="20" _id="60742"][/kc_column][kc_column width="2%" video_mute="no" _id="67508"][/kc_column][/kc_row][kc_row use_container="yes" _id="531051"][kc_column width="12/12" video_mute="no" _id="776805"][kc_spacing height="30px" _id="573264"][/kc_column][/kc_row][kc_row use_container="yes" _id="668448" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInLeft||"][kc_column width="55%" video_mute="no" _id="205124"][kc_column_text _id="538443"]Synthesis of nanopowders in solvothermal medium

The prospects for industrial use of nanomaterials are growing every day, especially those of nanostructured oxides. The production routes for these nanopowders are varied, but it will be imperative in the short term to have materials of excellent quality, for example without crystal defects or whose surface will not contain essential adsorbed species other than H2O or OH-. In addition, it is now important to develop clean and environmentally friendly synthetic routes. Among all the possible synthetic routes, the synthesis of nanopowders in a solvothermal medium has many advantages and responds in particular to the constraints described above. In fact, the thermohydrolysis process that occurs generally does not require secondary reagents, hence a "clean" reaction medium: which considerably limits pollutant releases.

Synthesis in supercritical water has been around for a long time in batch reactors. The main drawback of such a closed device is the thermal inertia of the reactor which must "resist" the combined effect of temperature and pressure, and the resulting temperature variations in the reaction medium. These limitations can be removed in a continuous device. The continuous supercritical water synthesis implemented by the PMDM axis has shown its ability to produce many simple and mixed oxides (Fe2O3, Fe3O4, CoFe2O4, TiFe2O4, TiO2, ZrO2, BaZrO3, ...). The current laboratory system allows an average production of 10 to 15 g / h of dry powder. Particles of nanometric sizes are generally very well crystallized and do not require any additional heat treatment, after recovery; this is a considerable advantage of this type of synthesis compared to syntheses by soft chemistry.

Contact :

Frédéric Demoisson – Phone: +33 (0)3 80 39 59 06 – frederic.demoisson[at]u-bourgogne.fr

[/kc_column_text][/kc_column][kc_column width="5%" video_mute="no" _id="103314"][/kc_column][kc_column width="40%" video_mute="no" _id="233004"][kc_carousel_images img_size="full" items_number="3" tablet="2" mobile="1" speed="500" pagination="__empty__" auto_play="__empty__" alt_text="__empty__" _id="536442" images="13001,13002,13003,13004,13005" onclick="lightbox" navigation="yes" nav_style="arrow" auto_height="yes"][/kc_column][/kc_row][kc_row use_container="yes" _id="942764"][kc_column width="12/12" video_mute="no" _id="785822"][kc_spacing height="30px" _id="842403"][/kc_column][/kc_row][kc_row use_container="yes" _id="783511" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInUp||"][kc_column width="12/12" video_mute="no" _id="385336"][kc_column_text _id="192520"]Massive parts

[/kc_column_text][/kc_column][/kc_row][kc_row use_container="yes" _id="42646" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInUp||"][kc_column width="12/12" video_mute="no" _id="996421"][kc_spacing height="30px" _id="487959"][kc_column_text _id="397742"]The PMDM department has a specialization in the development and characterization of sintered materials by hot compaction, as well as the assembly of dissimilar materials without addition of material, involving metallic materials (pure metals and alloys) and ceramics (oxides and carbides ). To establish the process / microstructure / properties relationships, our objective is to understand the elementary mechanisms that develop at different scales such as the germination and growth mechanisms, the densification mechanisms, phase transformations and structural transformations.

[/kc_column_text][kc_spacing height="30px" _id="149031"][/kc_column][/kc_row][kc_row use_container="yes" _id="570935" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInRight||" container_class="full bg-rs"][kc_column width="2%" video_mute="no" _id="410131"][/kc_column][kc_column width="45%" video_mute="no" _id="921185"][kc_spacing height="20" _id="581672"][kc_carousel_images img_size="full" items_number="3" tablet="2" mobile="1" speed="500" pagination="__empty__" auto_play="__empty__" alt_text="yes" _id="197628" images="13054,13055,12950,12951" onclick="lightbox" navigation="yes" nav_style="arrow" auto_height="yes"][kc_spacing height="20" _id="310616"][/kc_column][kc_column width="6%" video_mute="no" _id="147273"][/kc_column][kc_column width="45%" video_mute="no" _id="35105"][kc_spacing height="20" _id="489441"][kc_column_text _id="117845"]Compaction

We develop several tools and processes:

- flash sintering or SPS (Spark Plasma Sintering) under uni-axial load and heating by conduction / Joule effect: screening of materials / microstructures, dense materials with controlled microstructure, materials with a functional gradient, implementation of parts by self-assembly

- isostatic hot compaction (CIC) with isostatic stress and convection heating. It makes it possible to envisage different aspects: implementation of parts of complex shapes, dense materials with homogeneous microstructures, closure of the porosity (foundry defects, parts obtained by additive manufacturing, etc.), assembly by diffusion in the solid state.

Contacts :

Frédéric Bernard – Phone: +33 (0)3 80 39 61 25 – fbernard[at]u-bourgogne.fr

Sophie Le Gallet – Phone: +33 (0)3 80 39 61 63 – Sophie.Le-Gallet[at]u-bourgogne.fr

[/kc_column_text][kc_spacing height="20" _id="384274"][/kc_column][kc_column width="2%" video_mute="no" _id="459478"][/kc_column][/kc_row][kc_row use_container="yes" _id="998443"][kc_column width="12/12" video_mute="no" _id="711580"][kc_spacing height="30px" _id="37857"][/kc_column][/kc_row][kc_row use_container="yes" _id="493148" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInLeft||"][kc_column width="55%" video_mute="no" _id="785696"][kc_column_text _id="402526"]Additive manufacturing

The additive manufacturing process by laser micro-fusion on a powder bed (SLM: Sintering Laser Melting) consists of placing a bed of powder a few tens of micrometers thick on a support plate, then melting this powder according to the parameters. geometric defined from a CAD file. The molten powder is solidified quickly forming beads of solid material. At the end of this step, the support plate comes down to a layer thickness and a movable container deposits powder. Then the process starts again to develop another layer of material. This is repeated until the finished product.

Contacts :

Christophe Verdy – Phone:+33 (0)3 84 58 31 08 – Christophe.verdy@utbm.fr

[/kc_column_text][/kc_column][kc_column width="5%" video_mute="no" _id="420539"][/kc_column][kc_column width="40%" video_mute="no" _id="29573"][kc_carousel_images img_size="full" items_number="1" tablet="2" mobile="1" speed="500" pagination="__empty__" auto_play="__empty__" alt_text="yes" _id="519349" images="12980,12984,12981,12983,12985,12982" onclick="lightbox" navigation="yes" nav_style="arrow" auto_height="yes"][/kc_column][/kc_row][kc_row use_container="yes" _id="779611"][kc_column width="12/12" video_mute="no" _id="632156"][kc_spacing height="30px" _id="763363"][/kc_column][/kc_row][kc_row use_container="yes" _id="610370" cols_gap="{`kc-css`:{}}" force="__empty__" animate="fadeInRight||" container_class="full bg-rs"][kc_column width="2%" video_mute="no" _id="476939"][/kc_column][kc_column width="45%" video_mute="no" _id="309850"][kc_spacing height="20" _id="268506"][kc_carousel_images img_size="full" items_number="3" tablet="2" mobile="1" speed="500" pagination="__empty__" auto_play="__empty__" alt_text="yes" _id="648076" images="13033,13034,13035" onclick="lightbox" navigation="yes" nav_style="arrow" auto_height="yes"][kc_spacing height="20" _id="46945"][/kc_column][kc_column width="6%" video_mute="no" _id="775822"][/kc_column][kc_column width="45%" video_mute="no" _id="973520"][kc_spacing height="20" _id="304096"][kc_column_text _id="816645"]Durability of sintered materials

Optimizing the wear properties of metals and metal alloys developed by SPS and HIP, leading to an extension of the service life of parts in service condition, constitutes an important technical challenge. The processing parameters directly influence the microstructure and, therefore, the durability properties of the products obtained by powder metallurgy. The study of the durability of sintered materials is approached from several aspects:

- evaluation of mechanical (initial condition and in service conditions) and tribological properties;

- resistance to high temperature oxidation;

- weldability;

- modeling of structural changes in relation to the final properties.

Contacts :

Maria-Rosa Ardigo-Besnard – Phone: +33 (0)3 80 39 60 16 – maria-rosa.ardigo-besnard[at]u-bourgogne.fr

Jean-Philippe Chateau-Cornu – Phone: +33 (0)3 80 39 61 46 – jean-philippe.chateau-cornu@u-bourgogne.fr

[/kc_column_text][kc_spacing height="20" _id="995438"][/kc_column][kc_column width="2%" video_mute="no" _id="161433"][/kc_column][/kc_row]