ISITE BFC project: 4D printing and artificial materials

Currently booming and considered with artificial intelligence as one of the main pillars of the industry of the future, the field of 3D printing is currently at the heart of various industrial challenges. It is therefore in this context that 4D printing arouses high expectations around the theme of programmable matter and its applications. In Bourgogne Franche-Comté (BFC), many activities have emerged targeting radical innovations in 4D printing, a technology combining additive manufacturing processes and active (or intelligent) artificial materials.

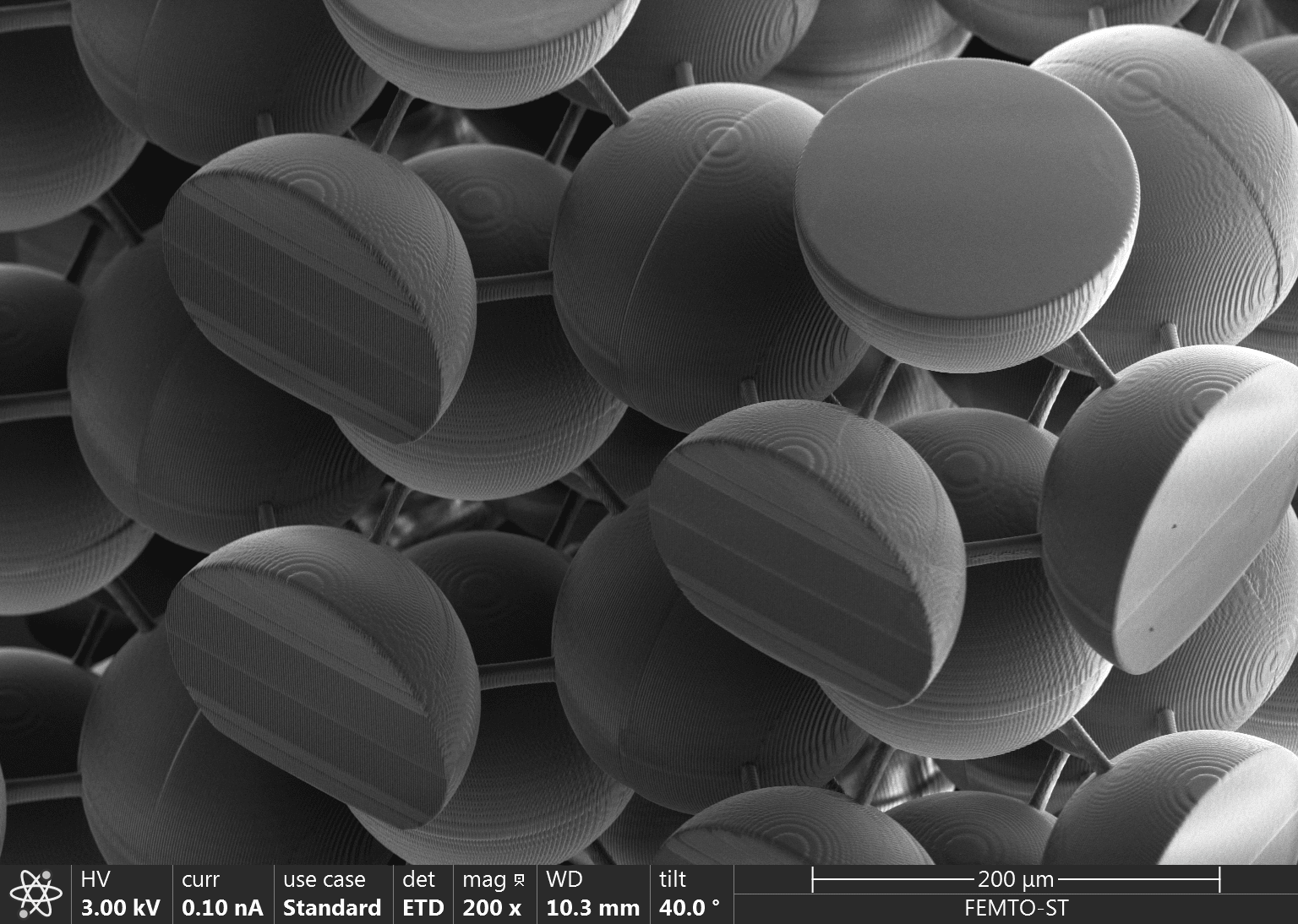

In order to promote this emergence, the ISITE 4D-META Project coordinated locally by Alexandre Bouhelier, CNRS Research Director and responsible for the ARCEN Carnot technological platform, aims to deploy the tools of 4D printing technology (programmable materials) for production. of artificial materials (meta-materials) at the regional level. This interdisciplinary project involves researchers from Besançon (dept MN2S-FEMTO-ST), UTBM (dept COMM-ICB) and Dijon (Dept Photonique-ICB).

4D printing “BFC model"

The “BFC model" 4D printing is defined as multi-scale, essentially additive manufacturing, with the vision of placing artificial materials made active under external energy stimulation. By placing 4D printing as a frontier object involving the convergence of actions, this interdisciplinary axis bringing together many disciplines available in the regional territory promotes the emergence of new paradigms of intelligent materials for promising applications in the industry of the future.

Thus, three research strands have been identified having as a guiding principle the development of 4D printing approaches of multi-scale structures and multi-active materials requiring various physics.

To achieve these objectives, the PMDM department in Dijon will provide its expertise concerning the sintering / compacting / assembly processes of the FLAIR platform and its associated EQUIPEX (CALHIPSO). Other FEMTO-ST departments may join the process (DMA). Industrial applications of gasket type for SOFC Fuel Cells, or any other application to be defined, where 4D metal or hybrid printing could provide relevant solutions.

- Local contact : Alexandre Bouhelier, alexandre.bouhelier@u-bourgogne.fr

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content: