Covid-19, to go further : EasyBreath adapters and filters for respirators

In collaboration with the CHU Dijon Bourgogne: Dossou Hounhouivou (Chief biomedical engineer), Sébastien Mirek (Doctor anesthesiologist-resuscitator), Rola Vrigneaud (Biomedical engineer) and Guillaume Koch (Biomedical engineer); members of the ICB laboratory’s OSNC team: Nicolas Pocholle (Sayens Study Engineer), Eric Bourillot and Eric Lesniewska, are developing filter adapters for EasyBreath masks from Decathlon for carers and patients and also for filter adapters for respirators from the company Bennett.

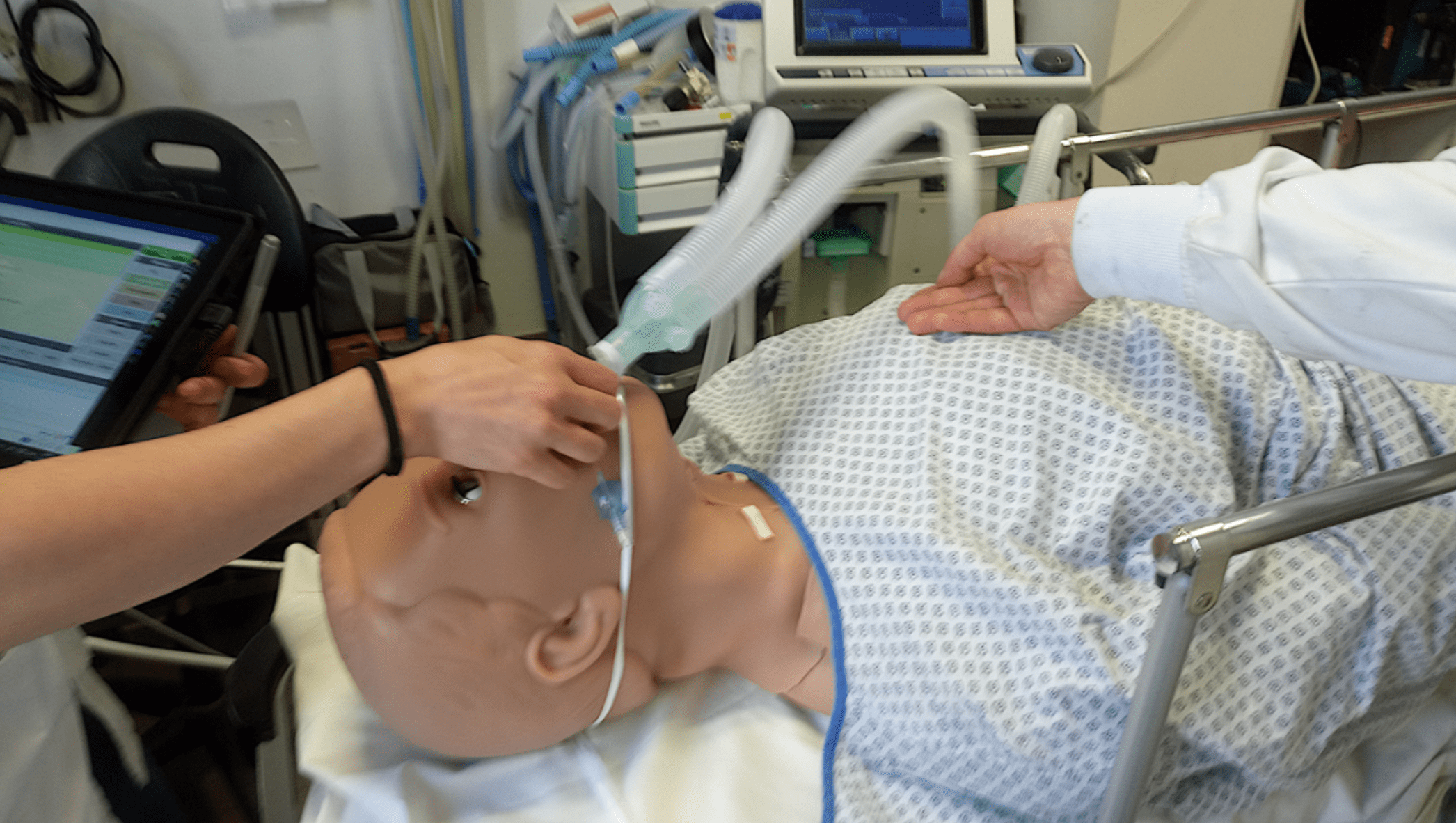

Figure 1: Device dummy test

EASYBREATH MASK ADAPTERS (DECATHLON)

The CHU Dijon received a donation of 70 masks Thursday, April 9 by the French company Decathlon. In this context, in collaboration with the CHU, the OSNC team has entirely designed adapters to protect caregivers during intubation of patients. A first production of about forty adapters was delivered Friday, April 17 afternoon at the hospital, another should be made for Tuesday, April 2. A second series will be produced for patients requiring only respiratory assistance without intubation (lighter pathology). Finally, a third model will be developed for emerging countries that cannot afford respirators. For this, the adapter will include 2 inlet / outlet ports for respiratory physiotherapy and will be developed in collaboration with the CHU Dijon.

Filter adapters for respirators

Bennett PB 800 series respirators present at the CHU Dijon, normally used for teaching, will be used in intensive care units and need to be rehabilitated due to a shortage by the manufacturer of the COVIDEN D / X 800 filter.

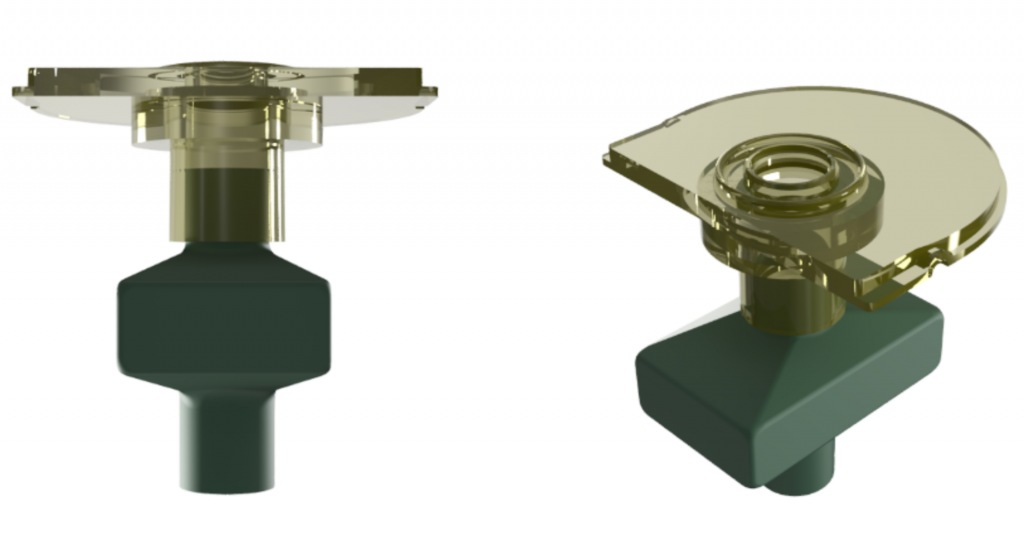

Also, the OSNC team has developed and produced adapters for filters of another type (COVIDEN STERIVENT S) for Bennett PB 800 series respirators. The adapter is produced by printing in two parts: FDM printing (Fused Deposition Modeling, molten wire deposition) in PETG or DLP (Digital Light Processing) in PMMA.

The leak tests were successfully carried out at the hospital.

Figure 2 : Realization of the adapter by 3D printing

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content: