CALHISPO project of the ICB laboratory on the front page of Journal du Palais

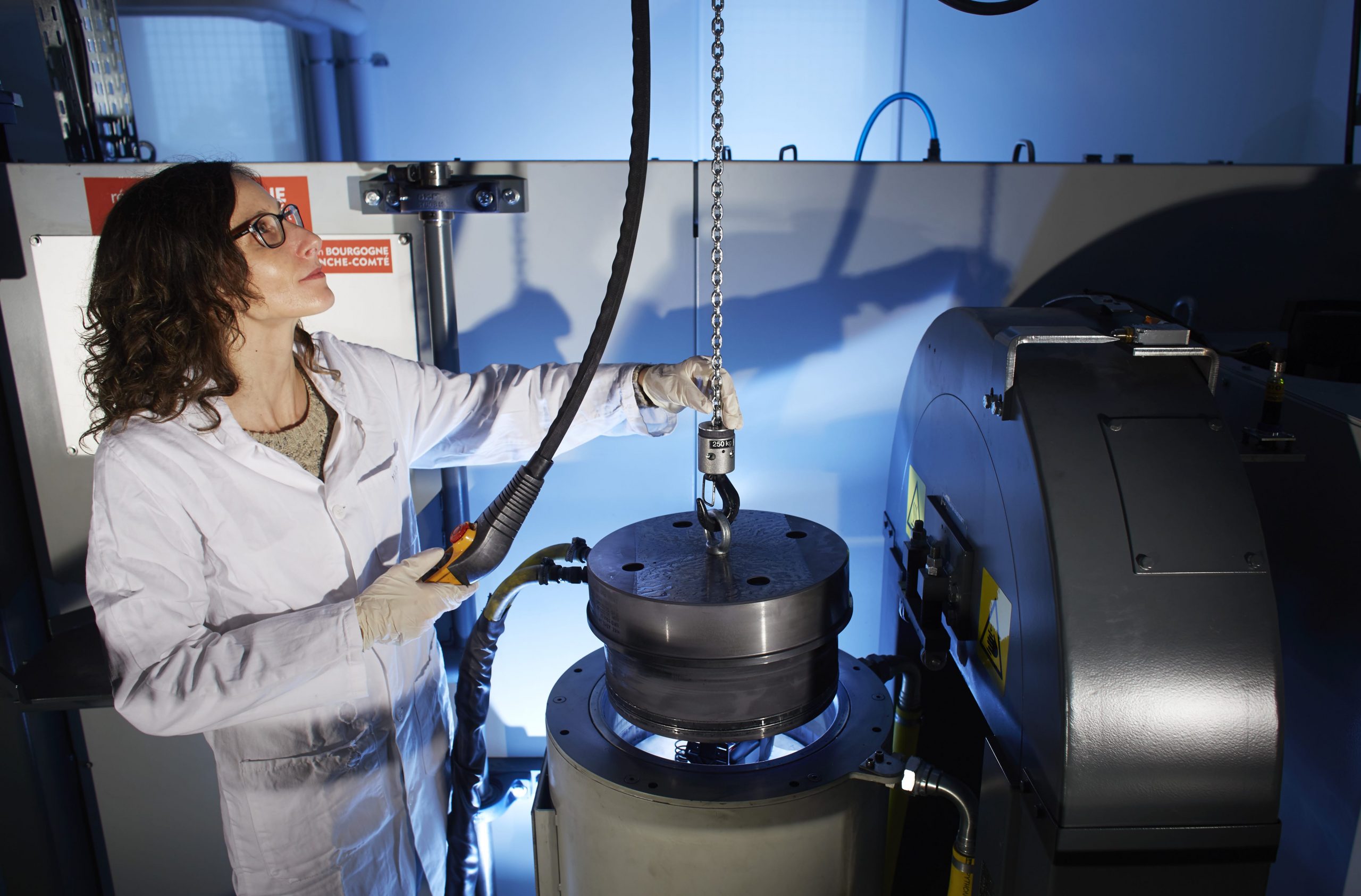

® A. Chezière / View of the upper part of the HIP enclosure installed at the Maison de la Métallurgie in Dijon.

“Calhipso, tout sauf de la poudre de Perlimpimpin"

His goal ? Defend, promote and develop research

Coordinated by UBFC (Bourgogne Franche-Comté University), CALHIPSO (Compaction and assembly of metal alloys by HIP, an InnOvante Solution) is an ambitious project for the implementation of HIP technology (“Hot Isostatic Pressing”, Hot Isostatic Compression ) in the metallurgical industry (aeronautics, defense, nuclear, etc.). This project proposes a global approach of experimentation, modeling and simulation which will make it possible to define HIP solutions tailored to industrial needs.

Coordinated by Frédéric Bernard, professor of physical chemistry at the University of Burgundy (uB, member of UBFC), this project launched on April 13th brings together partners demonstrating a long experience in the implementation of HIP technology: team of Prof. Bernard within the Interdisciplinary Carnot laboratory in Burgundy (ICB, UMR 6303 CNRS-UBFC), the Innovation laboratory for New Energy Technologies and nanomaterials at the CEA in Grenoble, the Materials Shaping Center ( UMR 7635 CNRS-Paris Sciences Lettres / Mines ParisTech) and the company Framatome. This partnership provides the CALHIPSO project with a rich scientific environment and complementary equipment both from the point of view of the manufacturing processes and that of the means of characterization.

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content: