Nanofabrication Center (CNF)

The NanoFabrication Center (CNF) is a component of the ARCEN-CARNOT technical platform. It benefits from the support of the French Network of Nanofabrication Renatech + power stations of the CNRS, as a “local power station”.

The CNF’s development and characterization equipment is made available to researchers, engineers, technicians and students in the laboratory as part of national and European projects, as well as to the entire scientific community (public research centers and private, university laboratories, private companies, SATT …) through services or access rights after training.

This equipment is divided into 3 areas: Thin layers, Lithographs and Engravings, Nanofab characterizations.

Laurent Markey

Aurore Andrieux

Contact

laurent.markey[at]u-bourgogne.fr

Phone : +33 (0)3 80 39 68 36

aurore.andrieux[at]u-bourgogne.fr

Phone : +33 (0)3 80 39 60 30

Thin layers

The CNF’s thin film deposition machine fleet is made up of:

- 1 thermal evaporation rack (ME300, Plassys)

- 2 e-beam evaporation frames, 1 of which with ionic assistance and thermal source (MEB400, Plassys and Elettrorava)

- 2 sputtering frames, 1 of which has a thermal evaporation source (MP300 and MEP300, Plassys)

- 1 plasma assisted CVD frame with inductive coupling (Plasmapro100 Cobra ICPCVD, Oxford Instruments)

Lithographs and engravings

The CNF has a 45 m² clean room with the necessary equipment for depositing and structuring lithography resins:

- Spin-coaters, hot plates

- 2 chemical hoods for deposits, chemical attacks and ultrasonic cleaning

- 1 mask aligner for UV lithography (MJB4, Süss MicroTec)

- 1 electronic nanoshaker (Pioneer, Raith)

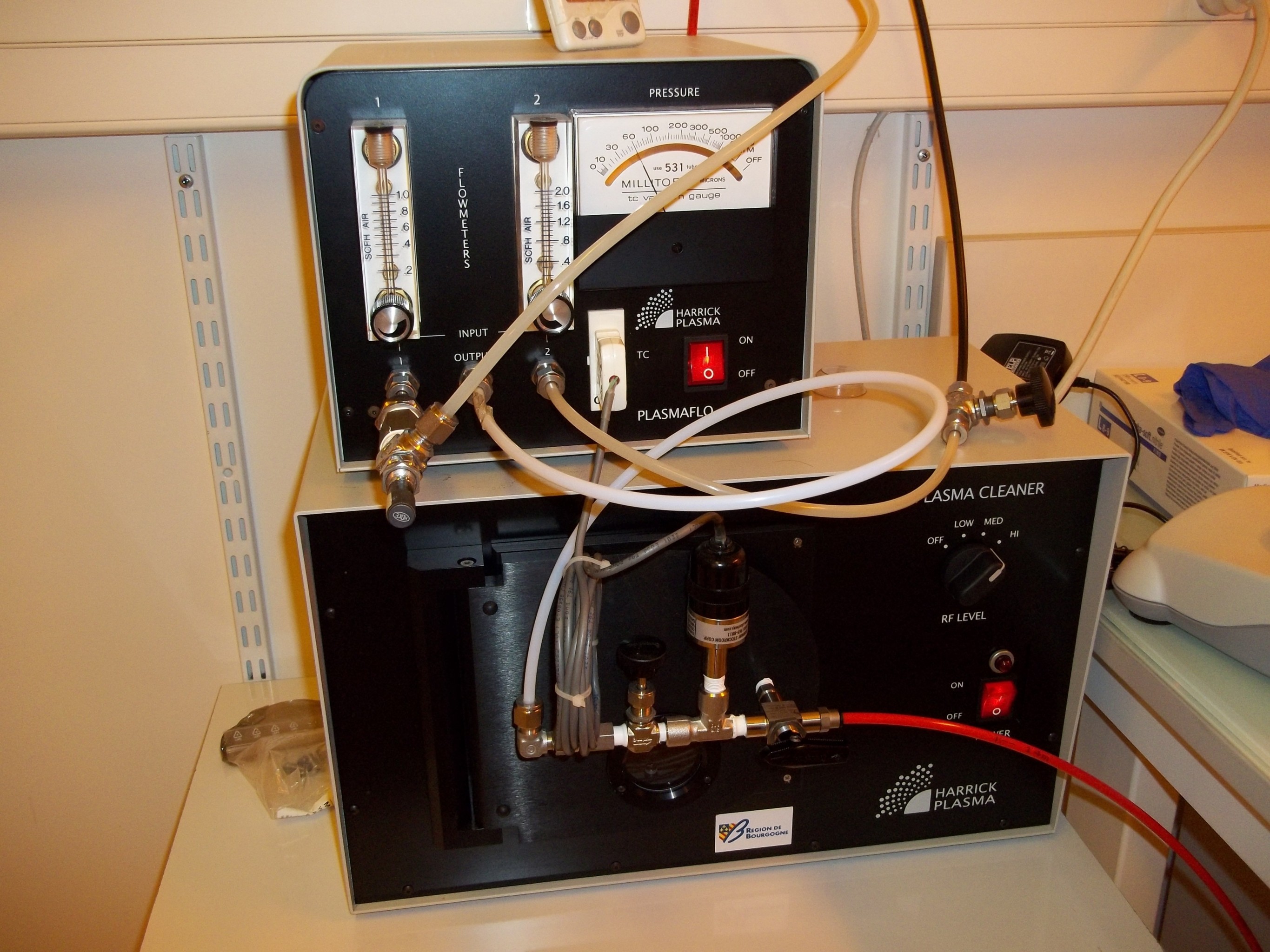

- 1 Metallizer (Edwards), 1 Plasma cleaner (Harrick)

As well as for surface preparation and etching of thin layers:

- 1 RIE etching frame with inductive coupling (Plasmalab System100 RIE-ICP, Oxford Instruments)

- An ionic machinist (MU400, Plassys) located in an annex room completes the list of equipment for this pole.

Nanofab characterizations

The achievements are often accompanied by characterizations (composition, structure, physical properties) which can be carried out by the CNF itself or by other components of the platform (cf. CNMC center)

The specific characterization tools for the control and validation of nanofabrication processes are managed by CNF members and located in the immediate vicinity of the equipment:

- 1 spectrometer in reflection for the thickness control of resins, deposits and etchings

- 1 SEM (JSM-6500F, JEOL) for the control of surfaces and structures (dimensional characteristics of structures, surface condition)

- 1 AFM for the measurement of roughness and dimensional characteristics of structures

- 1 high magnification optical microscope with camera for routine observations

- 1 spectroscopic ellipsometer for the estimation of the optical index of the layers

- kc_data:

- a:8:{i:0;s:0:"";s:4:"mode";s:2:"kc";s:3:"css";s:0:"";s:9:"max_width";s:0:"";s:7:"classes";s:0:"";s:9:"thumbnail";s:0:"";s:9:"collapsed";s:0:"";s:9:"optimized";s:0:"";}

- kc_raw_content: